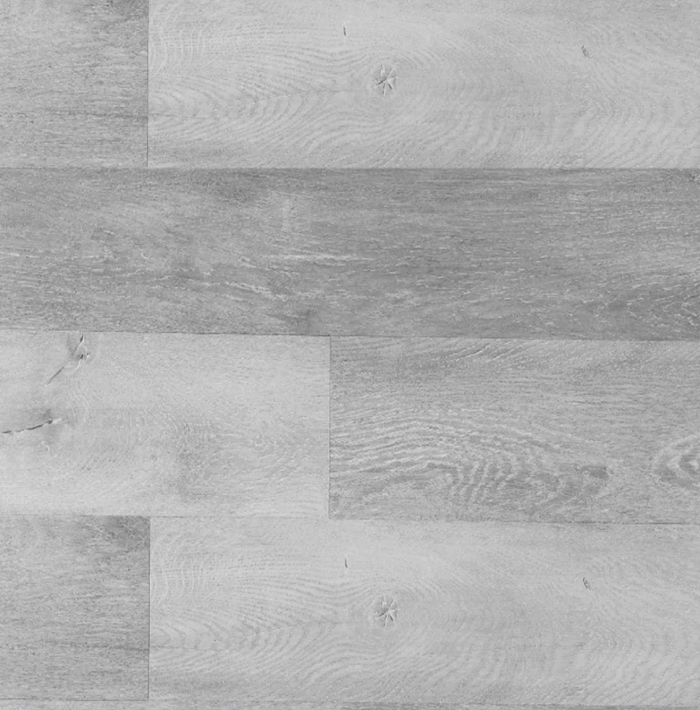

UNIQUE COMBINATION OF DESIGN, DURABILITY, AND SIMPLICITY

Permshield carries 100% waterproof, kid-proof, pet-proof luxury vinyl planks that fit beautifully in your home. Our products are designed to show off your style while maintaining all sustainability standards that promote the planet’s well-being and your own.Shop By Color

Browse styles by popular colorways to find floors that complement your furniture and decor.TRENDING COLORS

FEATURES THAT MATTER

Permshield features a rigid SPC core, a thick wear layer, a ceramic bead scratch resistant coating, a pre-attached IXPE underlayment, and so much more. Also, all of our flooring have key certifications like FloorScore and GreenGuard Gold to guarantee clean air that's safe for everyone wherever they are installed.about permshield

We started with a simple mission: to make floor shopping easy. Our goal is to improve the way you shop for, install, clean and live on your new floors. Now's the time to update your floors!